Custom made one piece DN1200

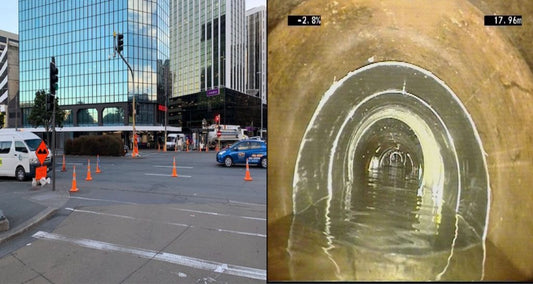

On a Major Victorian Government project, a DN1200 pipe with a high level of water infiltration required permanent sealing.

Project Description

Rangedale was contacted to rectify the problem and employed the Smart Lock Group to develop a solution, namely a specialised Smart Lock that could permanently repair and seal the pipe.The Smart Lock needed to measure 1200mm in diameter and be 400mm wide to completely seal the joint. Normally, a Smart Lock made for a pipe diameter of this size would be 200mm wide and consist of two pieces: however, with the high level of infiltration, the repair needed a one piece solution that would effectively seal and repair the open joint simultaneously.

Smart Lock Group has designed customised Smart Locks in the past for previous certified installers, clients and jobs when various or unique sizes have been required.

The large sheet of 316 grade stainless-steel had to be specially produced from the mill and sent to the engineering department for production. Once the custom made design was finalised, the manufacturing process was completed in under 3 weeks.

The installation was a challenging job due to the size of the pipe and size and weight of the equipment required for the install. After extensive project planning by the Rangedale team to ensure the safety of all crew members and equipment, an installation plan was finalised for the 7m deep shaft.

Specialised lifting equipment was required to hoist the large packer used to expand the Smart Lock in and out of the 7m shaft, with both the Smart Lock and packer required to be manually placed into position at the repair point.

Due to the high level of infiltration, two layers of fiberglass were used around the Smart Lock to create a permanent seal of the joint, combined with the stainless steel sleeve to create a structural repair and leave a completely clean and smooth internal bore for the pipe.

The installation process took only 3 hours to complete.

| Project Details | |

|---|---|

| Project: | Seal heavy infiltration with a specially made one piece DN1200. |

| End User: | Melbourne Water / Vic Roads |

| Contractor: | Rangedale Rehabilitation & Renewals |

| Country: | Australia |

| Construction Area: | Westgate Freeway |

| Installation Period | November 2020 |

| Area of Application: | DN1200 pipe under freeway |

| Number of Seals | 1 |

| Dominal DN (mm) | DN1200 |

| Challenge | Sheer size of the Smart Lock |