Putting the Pipe Before the Horse

Flemington Racecourse Manager Mr Michael Gooding contacted Rangedale Drainage and Civil with a problem. Mr Gooding’s maintenance team had noticed some ground subsidence in different locations throughout the racecourse’s training and race tracks. With preparations already underway for the fast-approaching Melbourne Cup Carnival, this situation was of enormous concern.

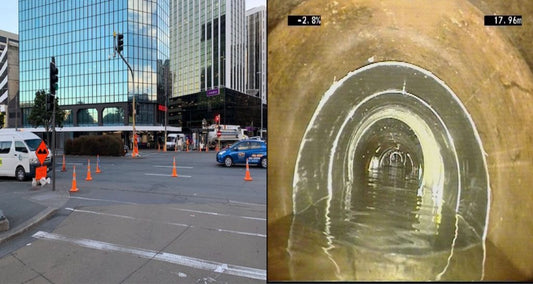

Garrie McLean, MD of Rangedale Drainage and Civil, conducted an urgent CCTV inspection of the pipe assets that run throughout the racecourse. This would determine if the subsidence was being caused by defective pipelines and what rehabilitation action would be necessary.

The CCTV inspections revealed numerous infiltration points through the various pipes rubber ring joints. Due to the enormous cost, time required, number of point repairs and risks of delay; particularly for the world-famous Flemington Spring Racing Carnival, excavation to repair these infiltrated pipelines was not possible.

Mr McLean, of Rangedale Drainage and Civil had no hesitation in recommending the installation of numerous Smart Locks to repair the leaking ring joints. Rangedale Drainage and Civil, an authorised installer of the Australian-made mechanical point repair system, swung into action, installing over 40 Smart Lock repairs on pipelines with diameters ranging from 300mm to 525mm.

Despite significant challenges including harsh weather conditions and high levels of infiltration at many points, Mr McLean said the whole project was successfully completed within the required timeframe and without disrupting the racing and carnival periods at Flemington – a definite highlight for the Smart Lock repair system. Even for the most infiltrated defective joints, it was no problem for the Smart Lock system to effectively seal and repair the joint.

Mr Gooding, Flemington Racecourse Manager said he could not be more pleased with the results:

“After the first day of installing the Smart Lock, all of our concerns were eased…It was amazing to see how the system worked to seal and repair pipeline defects and it was even more pleasing to be able to support an Australian designed and made product.”